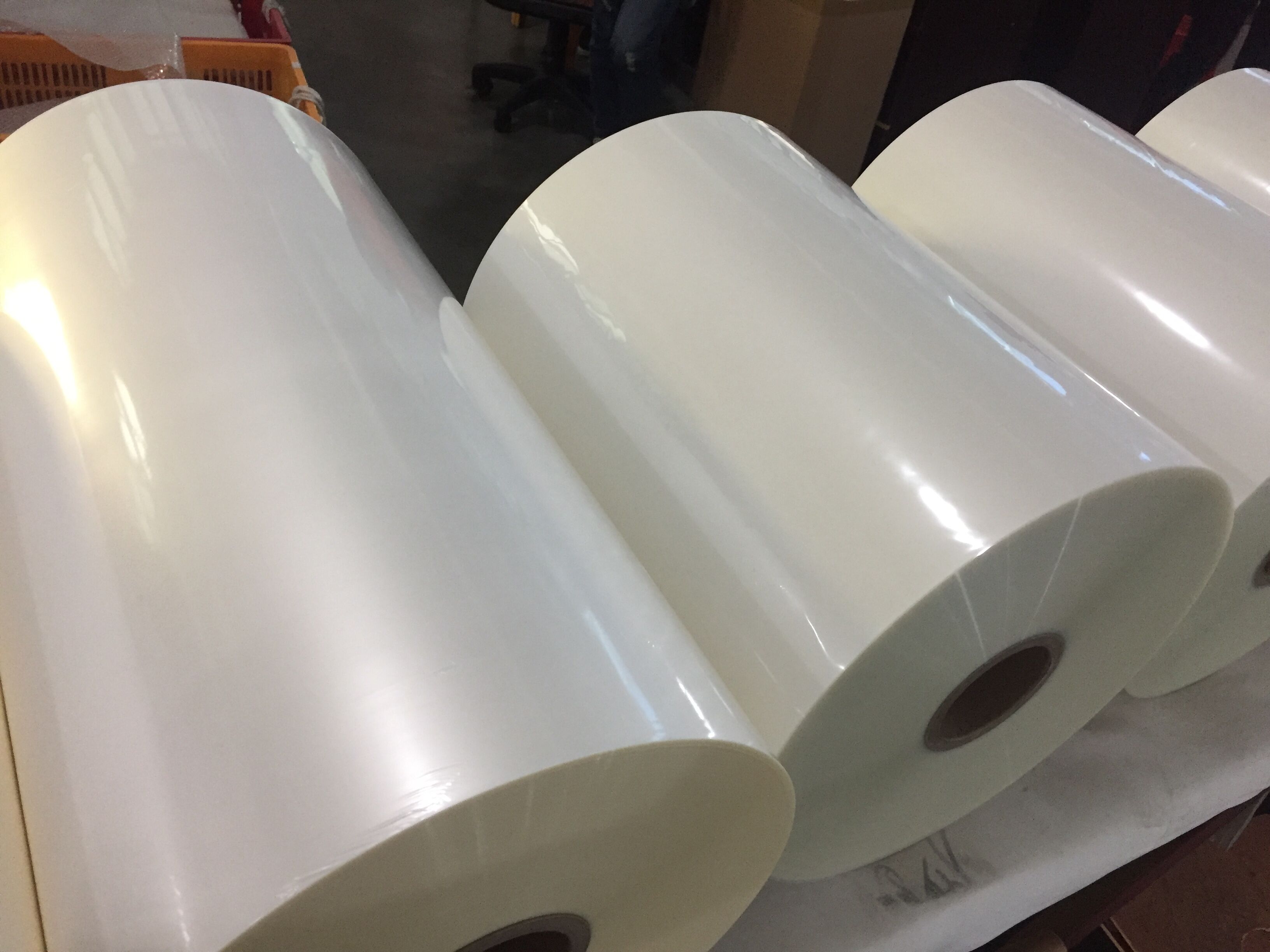

Guangdong New Era Composite Material Co., Ltd. is one of the top manufacturers for thermal lamination film in the

world. We have been engaged in the business of plastic films for

Printing & Packaging industry since 1980. In 2001, the company

named Chaoan New Era Industrial CO., Ltd. was formally established.

We introduced advanced technology and 6 units of automatic

production machineries, and started our own production of new types

of thermal lamination film that is environmental friendly. In March

2016, the company conducted shareholding reform and has changed to

GUANGDONG NEW ERA COMPOSITE MATERIAL CO., LTD.

We have the new plant with an area of 10,000 square meters, a plant

construction area of 23,000 square maters. We have developed our

four management principles, including ‘quality and efficiency,

innovation and development’. Based on these management principles,

we have constantly improved the internal management, and have

passed the Chinese Environmental Labeling certificate (Ⅱ type),

ISO9001-2008,ISO14001-2004, the national packaging product quality

supervision and inspection, SGS, and the test of 2008 American

consumer goods specified test parts.

As the first domestic pre-coating film production companies, New

Era Composite Co., Ltd. has been serving the high-end domestic

market and foreign markets as well. We continue to maintain good

long-term cooperation with well-known brands all over the world

because the market recognizes all our products’ quality,

performance, price and services.

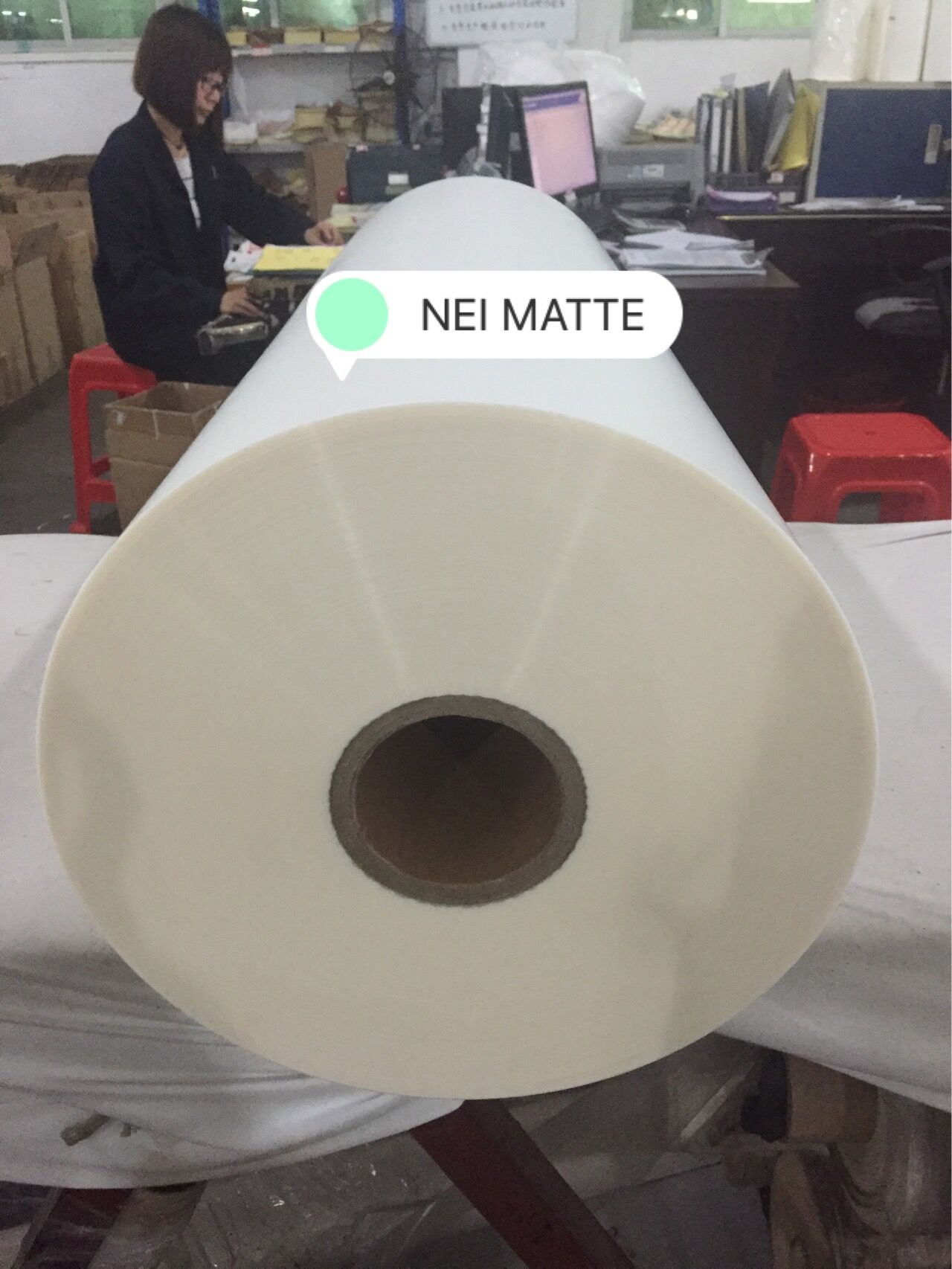

NEI (H.K.) Int'l Co., Limited is the subsidiary company of Guangdong New Era Composite Material

Co., Ltd. NEI (H.K.) Int'l Co., Limited is focusing on sales of

thermal lamination films while Guangdong New Era Composite

Material Co., Ltd. is focusing on production of thermal

lamination films.