Fashional Gloss Lamination Film Non-Toxic Odorless For Offset

Printing Photos

Glossy Specifications:

TYPE | THICKNESS (micron) |

GLOSSY | TOTAL | BASE | EVA |

17 | 12 | 5 |

18 | 12 | 6 |

20 | 12 | 8 |

22 | 12 | 10 |

23 | 15 | 8 |

25 | 15 | 10 |

27 | 15 | 12 |

30 | 15 | 15 |

42 | 28 | 14 |

WIDTH (mm) | 200 ~ 2210 |

LENGTH (m) | 100 ~ 8000 |

PAPER CORE | 25.4mm(1 inch) / 76mm (3 inch) |

BONDING | ≤2 |

CORONA TREATED | Double side |

SURFACE TENSION | 38 Dyne/cm ≤ 42 Dyne/cm |

LAMINATION TEMP. | 90±10°C |

ROLLER PRESSURE | 10 ~ 20Mpa |

LAMINATION SPEED | 20 ~ 70M |

Description:

The surface of the thermolaminated film is coated with

low-temperature molten resin extrusion, and the film can be

laminated to the paper product by heat and pressure. A variety of

surface treatments can add value to printed surfaces.

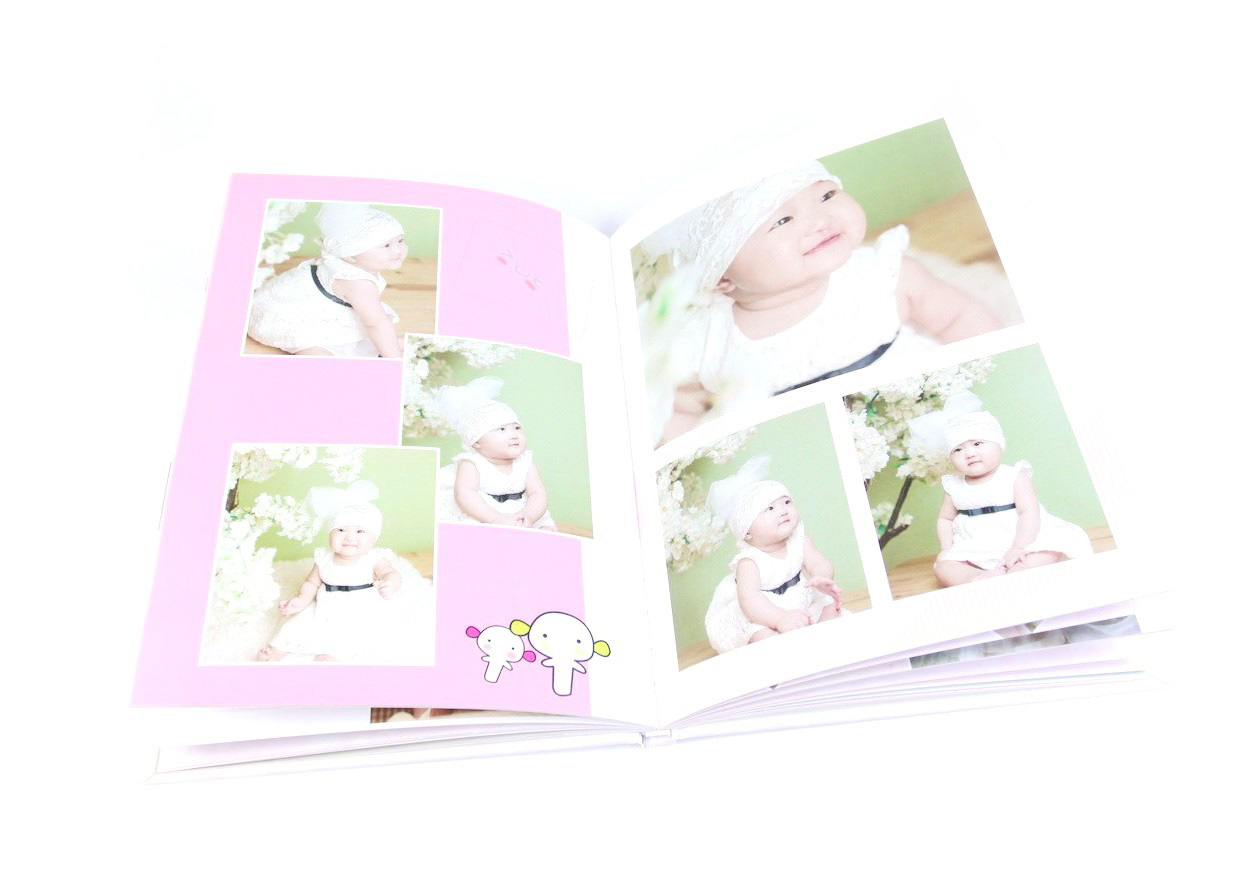

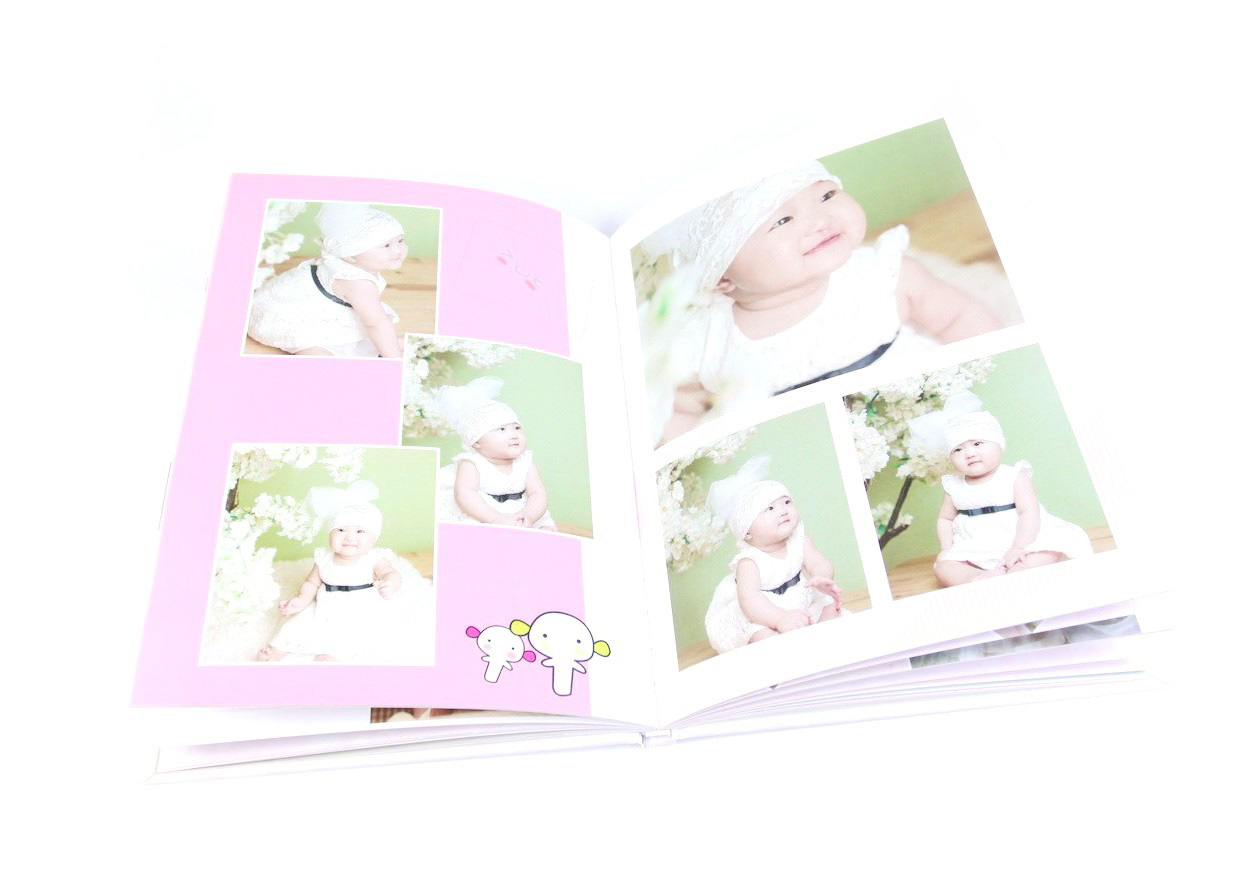

The glossy BOPP thermolaminated film provides a glossy colored

finish. Its use can enhance the appearance and increase the service

life of all laminated prints. BOPP thermolaminated film with good

performance and low price is ideal for all kinds of printed and

unprinted paper and board, including book covers, cosmetic

packaging, magazines, documents, shopping bags, diaries and more.

NEI BOPP thermal lamination film benefits!!!

1. Environmentally friendly: It is non-toxic, odorless or benzene-free

because it uses a non-solvent-based adhesive. It is environmentally

friendly and harmless to human health as no toxic gases or volatile

components are emitted during the laminating process.

2. Safe operation: The use of non-solvent-based adhesives eliminates

fire hazards caused by the use and storage of flammable solvents.

3. Excellent performance: Compared to wet laminating, thermal

laminating film improves the color saturation and brightness of

printed matter. It also has stronger powder absorption capacity and

adhesion. In addition, it can effectively prevent foaming or

separation from the stamping part during the lamination process.

Due to its strong bonding ability and surface tension, it can be

used in later processes, including point UV, hot stamping, die

cutting, and indentation processes.

4. Easy to operate: Once the required temperature and pressure are

reached, the lamination can be easily operated. No other special

techniques are required.

5. High efficiency: Production costs and Labour costs are greatly

reduced as there is no need for film waste, mixtures of adhesive

solvents or UV heat lamps (drying systems). Therefore, it also

saves production space.

6. Wide adaptability: Widely used in different types of laminating

machines, including wet and dry laminating machines. If a wet

laminator is used, only small adjustments to the machine are

required.

Why chooses NEI?

1. NEI has professional experience in the film industry since 1995, so

we have good quality control and after-sales service to support

you.

2. 10 years of export experience, including South America, North

America, the Middle East, Asia, Africa, Oceania and many other

countries, so we have a good reputation in these fields.

3. Compared to other thermolaminated films, our EVA glue is 100%

imported from Korea, ensuring the adhesion of our films.

4. Customized size and thickness according to customer requirements.

Labels can also be customized.

5. Rapid production and delivery.

6. Wide range of thermolaminated films and special films.

Special Instruction:

1. It is recommended to use NEI BOPP gloss hot laminating film with

roll temperature of 85 ~ 110°C and roll pressure of 10 ~ 20Mpa for

laminating. However, the optimal conditions depend on the speed and

dimensional stability of the laminator chosen.

2. It is recommended that the printed surface be sufficiently dry

before laminating and that one surface be sufficiently cooled

before laminating to another surface.